U. S. Steel Košice - Labortest, s.r.o.

Company info

The main reason for establishing the company was the need to fulfill strict legislative criteria for accreditation awards within the existing framework of the Slovak National Accreditation Service.

The objective is to broaden the scope and quality of the final quality control service provided at U. S. Steel Kosice, s.r.o., as well as gaining better credibility with our customers after the introduction of an unbiased quality control system in line with STN EN ISO/IEC 17025 criteria.

The company covers the following activities as per its certificate of incorporation

Chemical analyses,

mechanical tests

Special tests and analyses

for external customers

Consultancy in evaluation

of metallic and nonmetallic materials

Our company is a full member of the Slovak Testing Laboratories Association,

as well as a full member of the Association of Metallurgy, Mining Industry and Geology

Accreditation

The respective laboratories are fully accredited by the Slovak National Accreditation Service,

i.e. our laboratory results are recognized within Slovakia as well as abroad.

| Laboratory / Company | Certificate - Accreditation body - Standard / Law | Certificate No. |

|---|---|---|

|

Cokery Laboratory |

Accreditation certificate No. S-024 |

|

|

Cold Rolling Mill Laboratory |

Accreditation certificate No. S-010 |

|

|

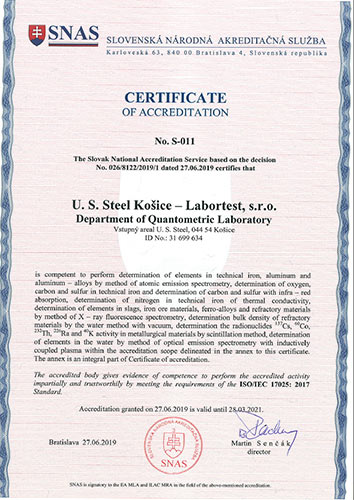

Quantometric Laboratory |

Accreditation certificate No. S-011 |

|

|

Mechanical Testing Laboratory |

Accreditation certificate No. S-012 |

|

|

U. S. Steel Košice Labortest, s.r.o. |

Certificate with the right to use a seal of testing laboratory |

|

Laboratories

» Cokery Laboratory

» Cold Rolling Mill Laboratory

» Quantometric Laboratory

» Mechanical Testing Laboratory

Cokery Laboratory

Is competent to perform chemical and physical analyses of solid fuels (coal and coke), gases, waste and underground waters, petroleum products and coke-oven chemicals products.

The accredited body gives evidence of competence to perform the accredited activity impartially and trustworthily by meeting the requirements of the ISO/IEC 17025:2005 Standard.

Accredited analyses

- Solid fuels (coal, coke) – determination of total water, analytical water, ash, volatile mater, carbon, hydrogen, nitrogen and sulfur by IR absorption and determination of gross and net calorific value

- Gases - determination of methane, hydrogen, oxygen, nitrogen, carbon dioxide, carbon monoxide, ethen, ethane and acetylene by GC chromatography

- Waste waters – determination of pH by electrochemical method, cyanide and chemical oxygen demand (Cr) by photometric method, polycyclic aromatic hydrocarbons (PAH) by GC MS chromatography

- Waste andunderground waters – determination of ammonia by photometric method, determination of chlorides, fluorides, nitrates, nitrites, phosphates and sulphates byIC chromatography

- Underground water – determination of permanganate index by potentiometric titration

Non-accredited analyses

Solid fuels:

- Dilatometer test of hard coal, determination ofchlorine and phosphoruscontent in the solid mineral fuels,crucible swelling number of hard coal, volatile mater in the brown coal, test sieving of coal and relative degree of oxidation in bituminous coal

Waste waters:

- Determination of sulphides, tiokyanatanes, phenol index, biochemical oxygen demand after n days(BOD n), nitrate, phosphorus, ammonium, nitrite, chloride, dissolved substances, suspended solids, sulphate, free and total ammonium, polycyclic aromatic hydrocarbons (PAH) in waste water

- Determination of organic and total nitrogen, hydrocarbons oil index in water

- Determination of total content of iron, silicon oxide, conductivity andoxygen content in furnace water

- Content determination (cyanide, ammonium, phenol, sulphate) in technological water of coke-oven gas desulfurization line

Gases:

- Analysis of ammonia, naphthalene,hydrogen sulphide and benzol losses in coke-oven gas

- Content determination (ammonium, hydrogen sulphide, carbon dioxide, hydrogen cyanide) in acid gas and waste gas of coke-oven gas desulfurization line

Petroleum products, coke-oven chemicals products:

- Determination of pour and flash point, cetane index in liquid fuels

- Content of toluene-insoluble mater in tar and tar oils

- Determination ofcarbon, hydrogen and nitrogen in tar

- Chemical composition of tar by GC-MS chromatography

- Determination of benzene, toluene, ethyl-benzene, xylem and naphthalene in benzol

- Determination of benzene and toluene in operational wash oils

- Determination of water, density, viscosity, sulfur, ash, acid number and mechanical impurities in oils

- Petroleum substances in scale samples

- Ethanol and ethyl glycol in resin

- Purity of liquid sulfur (water, acid content, organic matter, ash) at of coke-oven gas desulfurization line

- Technical sodium hydroxide analysis (sodium hydroxide content, total alkalinity, sodium carbonate content)

Cold Rolling Mill Laboratory

Is competent to carry out chemical and physical tests of surface-treated flat steel, technical iron, zinc, tin, aluminium and aluminium alloys, ground, surface and waste water, technological solutions, oils and emulsions.

The accredited body gives evidence of competence to perform the accredited activity impartially and trustworthily by meeting the requirements of the ISO/IEC 17025:2005 Standard.

Accredited analyses

- Tin coating mass determination

- Zinc coating mass determination

- Tin impurities content determination (As,Al,Bi,Fe,Cu,Pb,Sb,Cd,Zn) by spark optical emission spectrometry

- Zinc impurities content determination (Fe,Cu,Pb,Cd,Sn,Al,Si,Mg,Sb) by spark optical emission spectrometry

- Element determination (Cd, Fe,Mn, Zn and Cr total) in waste water

- Mercury (Hg) determination in ground, surface and waste water

- Hexavalent chrome (Cr6+) determination in waste water

- Technical iron chemical analysis – determination ofMn, Cr, Cu, Ni by flame atomic absorption spectrometry

- Technical iron chemical analysis – determination ofP, Mo, V, Si by spectrophotometric method

- Technical iron chemical analysis – determination ofSi by gravimetric method

- Chemical analysis of aluminium and its alloys – determination of Cu, Mg, Zn, Pb, Feby flame atomic absorption spectrometry

- Chemical analysis of aluminium and its alloys – determination of Si by gravimetric method

- Color difference test of coil coated metals

- Gloss determination of coil coated metals

- Adhesion after indentation (cupping test) of organic coated steel sheet. Erichsen test

- Adhesion after cross-cut test of organic coated steel sheet. Cross-cut test.

- Resistance of organic coating to cracking on bending. T-bend test

- Resistance of organic coating against to organic solvents (rubbing test). MEK-test

- Thickness of organic coating

- Measurement of the magnetic properties (magnetic polarization, magnetic induction, factor of anisotropy, specific losses, factor of ageing, specific losses after ageing) on electrical steel sheet by Epstein frame.

- Thickness of insulation layer on electrical steel sheet – Magnetic method

- Thickness of insulation layer on electrical steel sheet – Beta backscatter method

- Resistance of insulation layer on electrical steel sheet. Franklin test

- Fracture by reverse bend test of electrical steel sheet

- Surface roughness determination - parameters: Ra( Roughness average) and Pc (Peak count) ofzinc coated sheets

Non-accredited analyses

- Analyses of pickling media and products

- Analyses of tin, chromate, nickel and cooper electrolyte

- Specific tests of sheets surface (passivation and oxidation film, surface carbon determination)

- Analyses of degreasing and passivation solutions

- Analyses of oils, emulsions, dioctylsebacat

- Waste water analyses

- Chemical analyses of metal materials (tin, zinc, steel, iron, aluminium, cooper, nickel, ferroalloys)

- Chemical analyses ofinput materials (paints, acids, alkalis, salts, insulating materials, varnishes)

- Mercury determination in steeland powder materials

- Resistance of organic coating sheets in salt spray chamber

Quantometric Laboratory

Is competent to perform determination of elements in technical iron (low-alloy steel, cast iron), aluminium and aluminium alloys by spark atomic emission spectrometry, determination of oxygen and nitrogen in technical iron, determination of carbon and sulfur in technical iron and ferroalloys, determination of chemical composition of slag, iron ore materials, ferroalloys and refractory materials by x-ray fluorescence spectrometry, determination of bulk density of refractory materials, determination of radionuclide activities in metallurgical materials by scintillation method, determination of elements in the water by optical emission spectrometry with inductively coupled plasma, specific chemical, physical and thermal tests of metallurgical, ceramic and refractory materials.

The accredited body gives evidence of competence to perform the accredited activity impartially and trustworthily by meeting the requirements of the ISO/IEC 17025:2005 Standard.

Accredited analyses

- Chemical composition of low alloy steel byspark optical emission spectrometry

- Chemical composition of cast iron byspark optical emission spectrometry

- Chemical composition of aluminium and aluminium alloys by spark optical emission spectrometry

- Determination of oxygen and nitrogen in steel by infrared absorption and thermal conductivity method

- Determination of carbon and sulfur in steel, cast iron and ferroalloys by infrared absorption method

- X-ray fluorescence spectral analysis of slag, iron ore materials, ferromanganese, ferrosilicon and refractory materials

- Bulk density determination of refractory materials by the water method with vacuum

- Measurement of radionuclide activities(137Cs and 60Co) in steel by scintillation method

- Measurement of radionuclide activities(232Th, 226Ra, 40K) in metallurgical granular materials by scintillation method

- Determination of selected elements in the water by optical emission spectrometry with inductively coupled plasma

Non-accredited analyses

- Chemical analysis of powder materials by optical emission spectrometry with inductive coupled plasma

- Chemical analysis of converter slag, blast-furnace slag, sinter, iron-ore pellets, casting powders, lime, refractory products and raw materials by wet classical methods

- Determination of loss by ignition, loss by drying, bulk density, absorbability, apparent and true porosity of ceramic and refractory materials

- Thermal and mechanical tests of refractory products – cold crushing strength, modulus of rupture at ambient temperature, modulus of rapture at elevated temperature, refractoriness (pyrometric cone equivalent), refractoriness-under-load, permanent changes in dimension on heating, resistance tothermal shock, determination of ash fusibility.

- Physical and chemical tests of cements and heat-resistant concretes – chemical analysis, strength determination, determinationof setting time and soundness

- Sieving analyses of granular materials

Mechanical Testing Laboratory

Is competent to perform mechanical tests of metallic materials.

The accredited body gives evidence of competence to perform the accredited activity impartially and trustworthily by meeting the requirements of the ISO/IEC 17025:2005 Standard.

Accredited analyses

- Tensile test - determination of parameters ReH, ReL, Rp, Rt, Rm, A, Ae, Ag, Z at room temperature, at elevated temperature (50-450°C) on flat specimens with thickness 0,13 mm – 14,00 mm and round bars specimens to diameter f 20 mm.

- Tensile test of welded joints in transverse and longitudinal direction

- Tensile test - Bake hardening index determination (BH)

- Tensile test - Plastic strain ratio determination (r)

- Tensile test –Tensile strain hardening exponent determination (n)

- Charpy impact test (2-450) J in the temperature range: ( from -70°C to +30)°Candat -196°C

- Drop weight tear test DWTT - Proportion of ductilefracture determination in the temperature range:( from -70°Cto+30)°C

- Bend test – destructive tests on welds

- Bend test – zinc coating adhesion

- Rockwell hardness test (HRC, HRB, HRF, HR30T, HR15T)

- Brinell hardness test (HBW 10/3000, HBW 2,5/187,5)

- Vickers hardness test (HV 30, HV 10, HV 5)

- Erichsen cupping test – depth of the indentation

Non-accredited analyses

- Evaluation of earing tinned sheets

- Elevated temperature cut test of radiator hanging plugs

- Cartonplast - determination of compressive strength

CODE OF ETHICAL BUSINESS CONDUCT

of U. S. Steel Košice – Labortest, s.r.o. (Slovak version)

Personal Data Protection

U. S. Steel Kosice - Labortest, s. r. o. promises to oblige provisions of General Data Protection Relevation regulation Nr. 679/2016 (EU) and correspondent law of Slovak Republic Nr. 122/2013 Protection of Personal Data.

Contact

Executive management

Ladislav ROŽEK

Chief executive

|

+421 55 673 4431 +421 917 626 700 |

|

|

|

lrozek |

Martin HURA

Deputy testing manager

|

+421 55 673 4225 +421 917 626 701 |

|

|

|

mhura |

Eva KRAJŇÁKOVÁ

Secretary

|

+421 55 673 4431 +421 917 165 803 |

|

|

|

ekrajnakova |

Cokery Laboratory

Tomáš LACEK

Laboratory manager

|

+421 55 673 2926 +421 908 296 460 |

|

|

|

tlacek |

Jakub DEMKO

Deputy manager

|

+421 908 296 450 | |

|

|

jakubdemko |

Cold Rolling Mill Laboratory

Beata SVETLÍKOVA

Laboratory manager

|

+421 55 673 6090 +421 917 626 721 |

|

|

|

bsvetlikova |

Peter MAŇKOŠ

Deputy manager

|

+421 908 296 455 | |

|

|

pmankos |

Quantometric Laboratory

Alica RIDZOŇOVÁ

Laboratory manager

|

+421 55 673 4903 +421 917 626 724 |

|

|

|

aridzonova |

Maria MOCHNACKÁ

Deputy manager

|

+421 55 673 0122 +421 917 626 722 |

|

|

|

mmochnacka |

Mechanical Testing Laboratory

Miroslav GREŠKO

Laboratory manager

|

+421 55 673 6006 +421 917 626 726 |

|

|

|

MiroslavGresko |

Marián ŠKODI

Deputy manager

|

+421 945 432 193 | |

|

|

mskodi |

U. S. Steel Košice - Labortest, s.r.o.

Registered office:

Vstupný areál U. S. Steel

044 54 Košice

Slovak Republic

Ident. No.: 31 699 634

Commercial Register:

District Court Košice I

Sec. Sro, File No.: 5471/V

GPS : +48° 37' 35.78", +21° 11' 38.32"

POSTAL ADDRESS:

U. S. Steel Košice, s.r.o.

Vstupný areál U. S. Steel

044 54 Košice

Slovak Republic

BILLING INFORMATION:

ID No.: 36 199 222

VAT ID: SK7020000119

Commercial Register: District Court Kosice I, Sec.: Sro, File No.: 11711/V

CONTACTS:

>> Commercial Team

>> Subsidiaries

>> Customer Technical Service

>> Research & Development

>> Suppliers

>> Public Relations & Media

>> Editorial Office - Oceľ východu

>> Visitors Center

>> Foundation

>> U. S. Steel Ethics Line

>> Training and Testing of Contractors, Entry Permits

>> Fire Department

VISITING US:

Click here to get Google maps driving direction for visitors and suppliers

GPS coordinates:

48.624314 N, 21.188045 E –

You can also visit the website of our parent company United States Steel Corporation.

sk.uss.com

sk.uss.com